The origin of the company RDM (name of the founder René De Malzine) started at the beginning of the last century when the company was based on the Belgian territory.

During the First World War, the factory was transferred in the area of Paris (COLOMBES) for security reasons, and then moved to VERDUN (Meuse) …

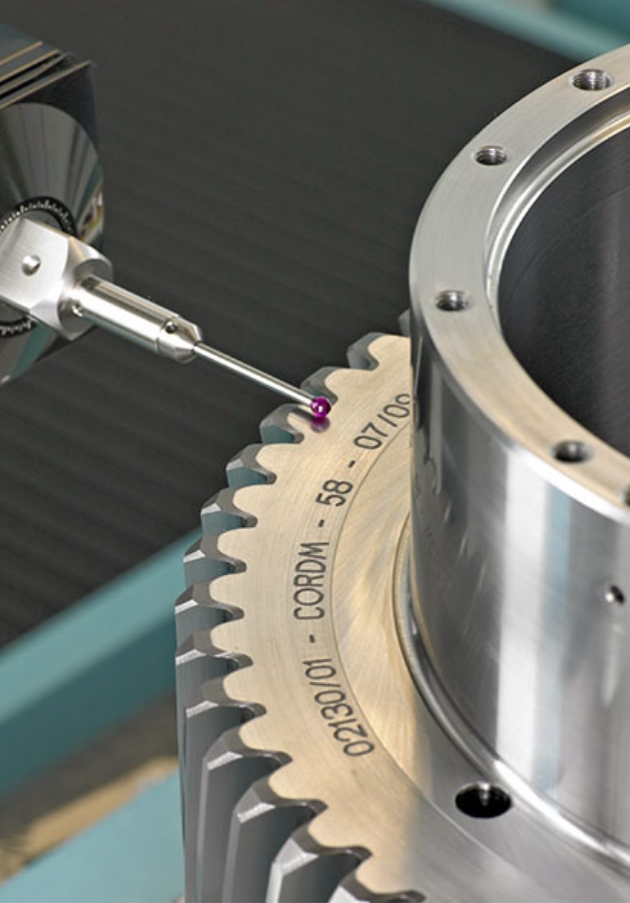

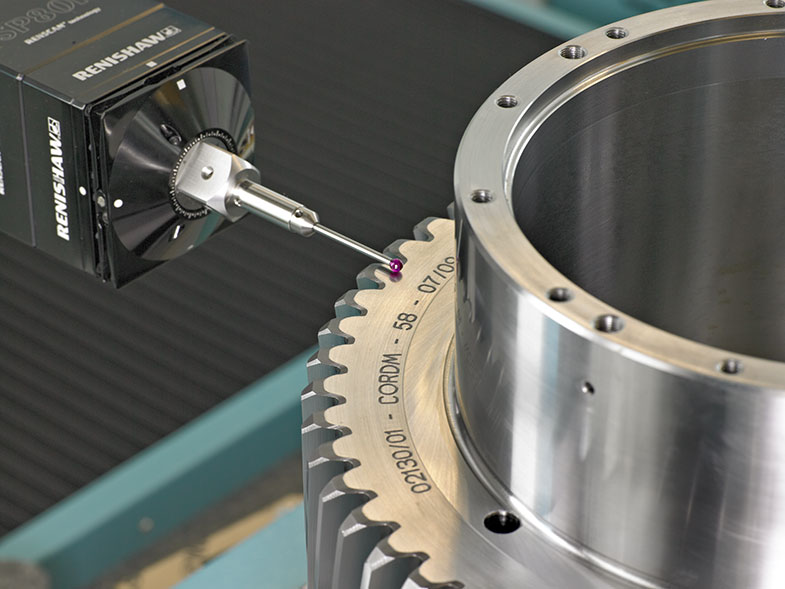

Thanks to our working procedures and our numerous quality certificates, we engage ourselves and assure a complete traceability of our products and professionalism at all time.

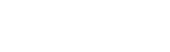

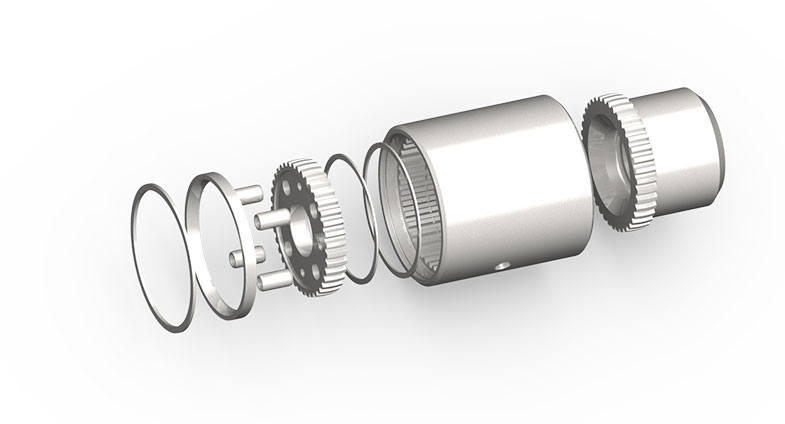

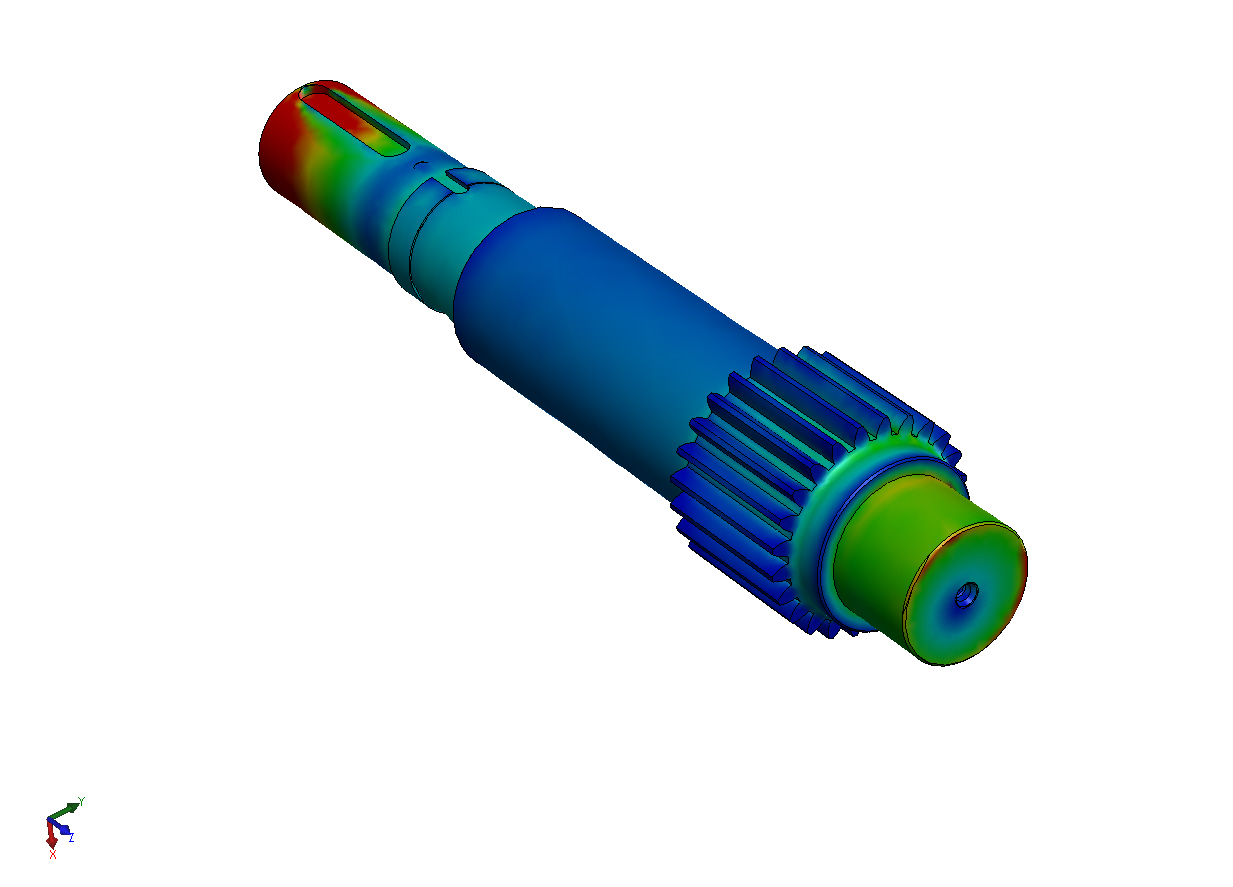

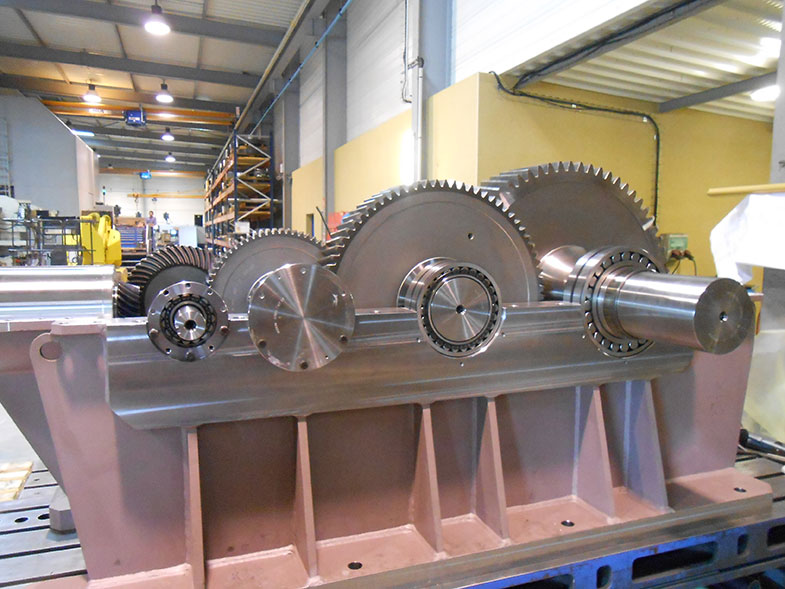

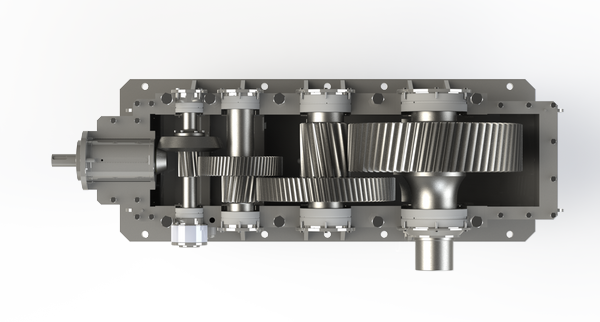

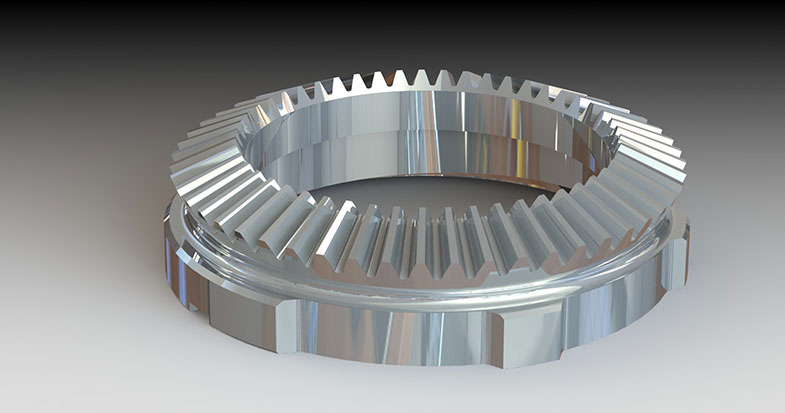

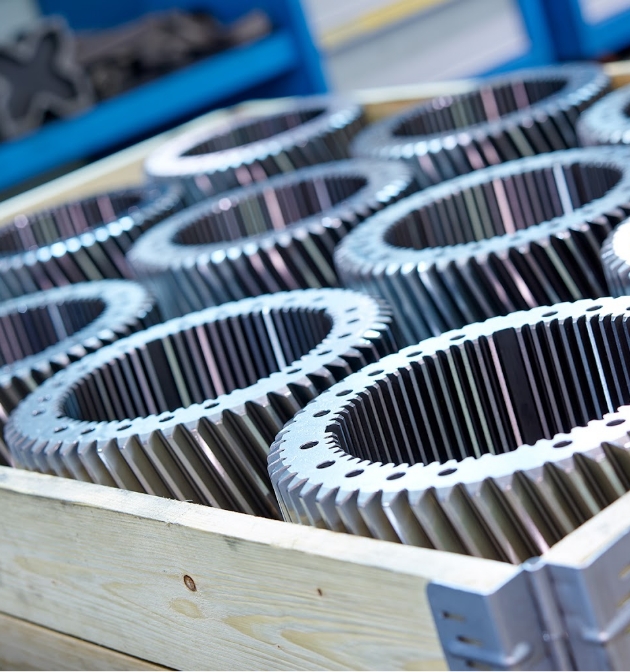

Since 1982, Cordm is your partner for all your industrial mechanical transmission projects: calculation and manufacture of precision gears, mechanical gearboxes, transmission shafts and gear trains. Thanks to a complete range of innovative equipment that is regularly reinforced by new investments, as well as unrivalled experience and know-how in gear machining and hobbing, Cordm can supply any type of mechanical gear and toothing (helical, spur, etc.), according to your drawings or sample parts and in strict compliance with your specifications: bevel, planetary, helical or rack and pinion gears, for example. Cordm provides a complete gear and pinion service for all your sectors of activity (rail transport, marine, crushing and mining or energy): calculation, milling, grinding, maintenance or balancing of transmission shafts. For each project, Cordm provides an expert response that perfectly suits your requirements, as well as high technical added value. With customer satisfaction at the heart of our business, each of our products (planetary gearboxes, splined shafts, planetary gearboxes, etc.) is accompanied by a strict quality policy.

Combined with our specialist skills in calculating, grinding and cutting gears and speed gearboxes, our expertise in precision industrial mechanics means that we can handle orders for complex parts and offer a complete range of mechanical transmission components: rack, pinion, gearwheel and transmission chain. In addition to standard references, our experts are attentive to all our customers’ requests and are able to produce customized parts, from chain or bevel pinions to simple or epicycloid gear trains and speed multipliers. Whatever the type or size of gear, rack, pinion or wheel required, our team puts its expertise at your service and develops unique solutions in line with the most demanding quality standards. For all your precision gearing projects, you can rely on Cordm.